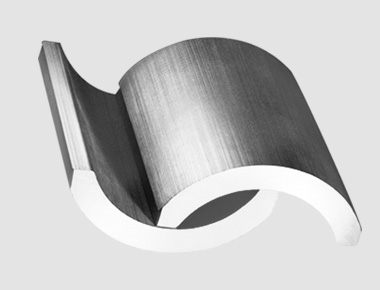

The four kinds of permanent magnets can all be used as industrial magnets. Owing to their different features and performance, they are applied in different industrial products. For example, neodymium iron boron magnets and ferrite magnets are mostly used for motors and generators. The maximum operating temperature of Alnico magnets is up to 550~600℃, they are universally used in various kinds of industrial instruments and meters. Compared to NdFeB magnets, SmCo magnets are more suitable working in high temperature environment. Besides, SmCo permanent magnets are very strong in resistance of corrosion and oxidation. Therefore they are widely used in national defense industry, military industry, microwave devices, sensor, magnetic gear, magnetic processor and electrical machine.

Servo Motor

Permanent magnet AC servo motor, also known as permanent magnet synchronous servo motor, uses high energy Neodymium-Iron-Boron permanent magnets to provide air gap magnetic field.

Servo motor as a rotor is a permanent magnet, the drive control of the U / V / W three-phase power, an electromagnetic field, the rotor is rotated under the action of this magnetic field, and the motor comes encoder feedback signal to the drive, the drive according to the feedback value and the target value, adjusting the angle of rotation of the rotor. It depends on the precision of the servo motor encoder accuracy (number of lines).

AC servo brushless motor is also divided into synchronous and asynchronous motors, motion control in general are currently using synchronous motors, large power range it can do a lot of power. Large inertia, the maximum rotational speed is low, and with the power increases rapidly decreased. Thus suitable for low speed applications running smoothly.

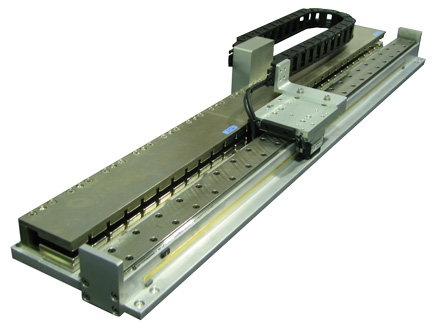

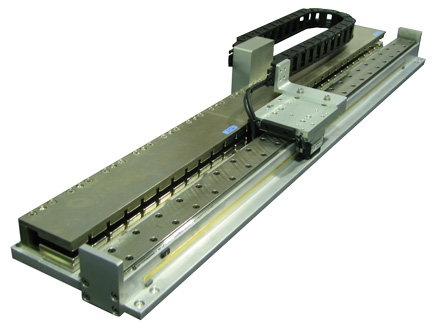

Linear motor

Linear Motors are mostly used in automatic control system, long time-running driving motors and machines that require large linear power in a short time and within short distance. Permanent magnetic linear motor magnet track, which replaces traditional secondary coil, can generate smooth and stable magnetic force although applied voltage fluctuation. It has merits of simple structure, non-contacting, non-wearing, low noise, quick speed, high positioning precision and flexible assembly。

Some of its applications are:

--- Logistics parcel sorting system

--- Automatic monitoring and feeding system

--- Battery sorting system